The ABC's of Running High Boost for the

1991 200TQ 20V Turbo and the 1992-96 Audi S4/S6

- Introduction

- Stock Boost Levels-How does the ECU control Boost

- Boost Graphs, Stock and Modified

- Stock Boost Gauge, Aftermarket Boost Gauges,

Pressure Conversion Info.

- ECU Self Diagnostic System-Fault Codes, Output Tests

- ECU System Components and Sensors Main page

with links to many topics

- Boost Problem Check List

- Overboost Fault Code? 2224? Check the boost hoses?

Check the MAF electrical connections?

- Waste Gate Controls

- Waste Gate Diaphragm Leak Testing

- Engine Control Unit (ECU) Vacuum/Boost Line

- Turbo Bypass Valve, Intercooler leaks

- Boost Hose Leaks, Samco Hoses

- Vacuum Leaks-Breather Hoses!

- Are you using the correct Spark Plugs?

- Ignition Wires? Distributor Cap?

- Ignition misfire on S4/S6 with coil over

direct ignition system?

- Are you using the correct Distributor Rotor on

the 1991 200TQ 20V with 3B engine?

- Knock Sensor Intermittent? Hesitation? Low Power?

- Air Temp Sensor

- O2 Sensor Replacement

- Fuel Filter Clogged or restrictive?

Fuel Contamination?

- Fuel Pressure Regulator diaphragm leaking?

Regulator Vacuum/Boost Hose Leaking, disconnected ?

- Multi-Function Temp. Sensor-Defective (3B Engine)?

- ECU - Coolant Temp Sensor Resistance Check,

Wiring check

- Check ECU connector terminals for corrosion

- Check Engine Ground Cable and Intake Manifold

Ground wires

- Throttle Cable Adjustment

- Throttle Switch/Potentiometer - Defective?

- Check Basic engine timing, flywheel, camshaft

and distributor rotor position

- Altitude Sensor ok?

- Idle Stabilizer Valve (ISV)

- Idle Speed/Mixture Adjustment?

- Fuel Injectors

- Coolant Pipe O-Rings, Seal and Turbo coolant

hose replacement

- Thermostat and other Cooling system checks

- Failed Emissions Test? Go to

Smogsite.com a great web site

with Emissions and Fuel Injection Info.

- Exhaust System Issues

- Drive Train Issues

- Important Safety Information

Introduction

It should be your responsibility (or your mechanics) to check out

and verify all the ECU and Fuel Injection system components mounted on

your engine are working correctly BEFORE you do any type of modification

that will raise the boost on your vehicle.

Raising the boost on a high mileage car isn't a great idea UNTIL you get

the stock system working correctly as it was originally designed when

it left the factory. If you install a stiffer Waste Gate spring or use

a valve connected to boost pressure to add pressure on top of the Waste

Gate Diaphragm, you may be unaware if the engine ECU/Fuel system components

are not working correctly, because the boost may be raised regardless

of the condition of the stock system components.

Whenever I purchase a used Turbocharged Audi, I check the compression

or do a leak down pressure test to verify the engine valves, rings, and

head gasket are in good shape. This leak down test is better than a basic

compression test and involves pressurizing the cylinder with air and measuring

the amount of leakage out of the cylinder.

This can pin point cylinder leakage out of the intake or exhaust valves,

past the rings, or through the head gasket. I replace the plugs, air filter,

and fuel filter and change the engine oil. I check/replace the O2 sensor.

I replace the valve cover gasket and any suspect breather or vacuum hoses.

I make sure the timing belt has been replaced at the suggested 60-90K

interval. I remove the lower Intercooler/turbo hose(s) and inspect them,

I check/replace the accordion style hose at the Intercooler connection.

It is also very important to check/replace the turbo bypass valve.

On the 1991 200TQ, it is important to Check/Replace the small Bypass valve

hose (vacuum/boost hose) that connects from the bypass valve to the small

fitting at the back of the intake manifold. On the 1992-95 S4/S6, you

may want to remove the black plastic firewall cover, and replace the crimped

on hose clamps at the ECU vacuum/pressure hose where it connects to the

clear moisture trap (Looks like a empty fuel filter) as these hose can

blow off as the boost goes up.

You can also pressure test the intake/boost hoses, by making an adapter

that is inserted into the hose between the MAF and the turbo, and then

apply regulated compressed air (~15psi) and pressure test the hoses from

the turbo inlet, out the turbo exit hose, through the Intercooler, and

into the throttle. If you are running the 1+ type ECU mods, which produce

over 20psi of boost, using the Samco boost hoses may save your screamin

K24 turbo some day.

I check the operation of the idle/potentiometer throttle switch, and I

remove and clean the idle stabilizer valve. I check the ECU measurement

block values (10 values) to ensure the ECU is operating the engine as

expected. If a problem with the mixture adjustment shows up, the intake

vacuum hoses, or the fuel pressure may need to be checked.

The cooling system integrity should be accessed. Replacing the thermostat,

and all the coolant hoses, the heater control valve, the heater core to

engine hoses, the radiator fan temperature sensor, the after-run temp

sensor, and the Multi-Function temperature sensor is also a good idea

on vehicles with over 100k miles.

You don't want a $10 hose ruining your expensive 20V engine when the hose

blows and causes overheating and a possible blown headgasket! Once I complete

the replacement of these many high mileage components, and ensure the

engine/ECU is operating correctly, I can rest assured, and I don't need

to "guess" if they are ok if the car starts running poorly.

Don't get lazy and "assume" these components are ok, just bite the bullet

and inspect or replace them as necessary. NOTE: Increasing the boost on

your vehicle may change the emissions output which may not be legal in

your area.

Stock Boost Levels-How does the ECU

control Boost?

The 1991 200TQ with 20V Turbo Engine was

designed to run a maximum of 1.825 bar boost (absolute) or ~12 psi gauge

pressure, as set by the Motronic Engine Control Unit (ECU).

The 1992-96 Audi S4 in overboost mode will have boost set to about 2.15

bar absolute. The actual boost produced will vary depending on engine

RPM, air temperature, fuel quality, and altitude. The 20V boost control

system is different than what was used on the earlier 10V Audi Turbo engines.

The ECU uses the Waste Gate solenoid to send boost to the lower chamber

in the waste gate to open up the waste gate at the appropriate boost level.

The Waste Gate solenoid valve is designed to be open with no electrical

signal applied, which will send turbo boost pressure directly to the lower

chamber in the waste gate and open the waste gate at a pressure only determined

by the stiffness of the waste gate spring.

When the waste gate solenoid is energized with a high duty cycle, (more

on time) the waste gate solenoid will prevent boost pressure from reaching

the waste gate lower chamber, and allow the boost pressure to climb higher.

The boost will climb, until the required boost level set in the ECU is

reached, at which point, the duty cycle percentage (%) to the waste gate

solenoid will be reduced, so the boost pressure will once again be sent

to the lower chamber in the waste gate diaphragm and the boost pressure

will be controlled. In the stock 20V engines, this corresponds to about

1.4-1.5 bar of boost as controlled by the waste gate spring. If you completely

remove the lower waste gate hose, or block it off, the waste gate will

only open when "exhaust" pressure acting on the waste gate valve face,

exceeds the waste gate spring pressure.

This is why a modified 20V ECU can make 2.25 bar absolute boost pressure,

even with the stock waste gate spring installed. The ECU uses a barometric

sensor to monitor the altitude the vehicle is at, and will trim back the

boost slightly as the altitude increases above 3900 feet. For example,

in the 1991 200TQ 20V, the boost will be reduced to about 1.715 bar absolute,

when the altitude is above 8500 feet [1].

Stock Digital Boost Gauge, Aftermarket Boost Gauge, Pressure

Conversion Info.

The stock digital boost gauge located in the instrument cluster displays

the intake manifold "absolute" boost pressure, from ~0.0 bar to 2.0

bar. The S4 boost gauge will read up to 2.5 bar on the 1992 models.

Some of the later Canadian S4 models also have the boost gauge.

For more details, go to the Stock Boost Gauge

page

Self Diagnostic System-Fault Codes

The self-diagnostic system test should be run before you have your stock

ECU modified, to make sure that there are no faults in any of the components

(knock sensors, coolant/air temp sensors, throttle switch etc.) that the

ECU relies on for correct engine operation. You need to do a 3rd gear

full throttle run to exercise this diagnostic system correctly.

The 1991 200TQ's with the Bosch Motronic ECU, have a non volatile memory

for the fault codes that can be read later even if the engine has been

turned off after the test drive. The ECU system OUTPUT tests should also

be done on the stock ECU before doing any modifications to verify that

the Wastegate Solenoid, the Carbon Canister valve, the idle stabilizer

valve and the fuel injectors are working correctly.

In some cases the ECU internal drive transistors for these solenoids can

be defective and will prevent correct operation of the engines fuel and

boost control systems. If there is a problem with any of the solenoids

or the internal operation of the ECU, this needs to be known BEFORE you

send in a ECU for modification.

Go to the

20V ECU Fault Code page at this web

site to run these Output tests.

Boost Problem Checklist

Here is a checklist you can go through when you have low or high boost

problems.

LOW BOOST or Running poor issues

- Check for any stored ECU fault codes, are the knock sensors working

ok?

- Read the Measurement block values using the VAG-COM, look for anything

out of the range

- Check basic engine timing, flywheel, camshaft and distributor rotor

position

- Check Throttle Cable Adjustment

- Check Air Filter, is it really clogged up?

- Check/Replace the Turbo Bypass Valve, check small vacuum/boost hose

to this valve

- Check Idle Stabilizer Hoses, and other small vacuum/boost hoses

- Check basic fuel pressure and correct operation of the rising rate

fuel pressure action by applying vacuum or boost to the vacuum/boost

hose connection

- Check fuel pressure regulator for leaking into the vacuum/boost

hose fitting (rich running)

- Check ECU moisture trap hoses (fuel filter lookin thang) behind

black firewall cover (AAN S4/S6)

- Check ECU Connector Terminals for corrosion, remove connector and

use contact cleaner

- Replace small vacuum hose from Bypass valve to Intake Manifold (3B

engine)

- Check the Operation of the Multi-Function Temp Sensor (1991 200Tq

20V Only)

- Temporarily disconnect Multi-Function Temp Sensor 4 pin connector

and recheck boost output (1991 200Tq 20V Only)

- Remove and inspect the Intercooler exit hose (Ribbed Hose) and the

lower turbo exit pressure hose for leaks.

- Check the rubber hose between the intake pipe and the throttle body.

- Check Vacuum hoses and their connections at the back of the intake

manifold

- Check/Replace the coolant thermostat, is the engine running too

cold? or too hot?

- Check Engine Coolant Temperature Sensor Resistance and connector

wiring

- Check the operation of the Waste Gate Solenoid using the ECU Output

Test

- Check Waste Gate Solenoid hoses

- Check Air Temp sensor resistance at the ECU, and Repair the Air

Temp Sensor wiring connections if needed.

- Check Throttle Position Switch/Potentiometer for intermittent operation

- Check Altitude Sensor Voltage Output and wiring between sensor and

ECU

- Plug or pinch off hose to lower waste gate and check for maximum

boost and overboost cutout

- Check Waste Gate for sticking open, defective spring?

- Check the Exhaust System Back pressure, possible exhaust restriction

- Inspect the Turbo inlet vanes and end play, has the turbo compressor

nut left the building? or the turbo seized up, broken in half, or

otherwise gone south?

OVERBOOST PROBLEMS (BOOST TOO HIGH)

- Check Lower Waste Gate Hose from Intake Manifold for leaks/restrictions

- Check the operation of the Waste Gate Solenoid using the ECU Output

Test

- Check Vacuum/Boost Hose from Intake Manifold to Engine Control Unit

(ECU) for leaks

- Pressure test the intake/boost hoses using hose adapter and compressed

air regulator adjusted to 15psi.

- Check and clean the electrical connections at the MAF sensor

- Check Waste Gate Diaphragm for Leaks

- Check Waste Gate Valve for sticking or restricted movement

Overboost Cutout?

ECU fault code 2224? If you are encountering an overboost condition

which is causing the ECU to cut the fuel pump, and you have stored the

2224 ECU fault code, here are some items to check out.

You may have a leaking wastegate Diaphragm, test the wastegate diaphragm

for leaks below.

You could also have a leak in the boost hoses between the turbo exit

connection and the throttle body.

If you have a hand pump or an air compressor, you can make up an adapter

to fit into the hose that connects to the turbo inlet, and this will

allow you to pressurize the air from the turbo inlet, through the turbo

exit hose, through the intercooler, from the intercooler exit hose,

and from the metal intake pipe to the throttle body and check for any

leaks. Use a pressure regulator set to about 15psi if you are using

an air compressor.

You can also do a visual check of the turbo exit hose underneath the

car and look for any signs of oil leaking out of the turbo exit hose,

indicating a leak. Normally a small amount of oil vapors and mist are

sucked in by the turbo from the crankcase breather system, and this

oil mist will typically show up outside the hoses, or intercooler connections

if a pressure leak is occurring.

Check and or replace the ribbed intercooler exit hose as well, these

often split open on the bottom side, in-between the wire re-enforced

rib areas, due to the crankcase breather oil mist in the system. Removing

the hoses and inspecting them is also a good idea on high mileage engines.

If you don't have any leaks in these hoses, check the vacuum/boost hose

that connects from the back of the intake manifold to the ECU inside

the car.

See below for details.

I have run across a couple of 20V Turbo cars which had a 2224 code stored

inside the ECU and were getting the overboost fuel pump cutout, even

though the boost was only going up to 1.0-1.2 bar.

In the first case this would occur only when the throttle was quickly

floored, and would not happen if the throttle was gradually opened all

the way. In the first case, it ended up being a defective MAF sensor.

In the other case it was only a poor connection at the MAF sensor.

Try using some electronic contact cleaner on the MAF connector and terminals,

and see if the overboost problem is eliminated.

Waste Gate Controls

The Waste Gate solenoid connecting hoses should be checked for leaks and

the ECU Waste Gate Solenoid "Output Test" should be run on the Waste Gate

Solenoid, as these solenoids are often found to be defective on the 20V

engine.

Go to

20V wastegate controls section for more

details.

NOTE: On the 20V turbo 5 cylinder engines, there is NOT supposed to be

any hose connected to the top of the waste gate cap fitting. It should

be left open to the atmosphere.

LEAK TEST THE WASTE

GATE DIAPHRAGM

You can use a hand vacuum pump to test the waste gate diaphragm for

leaks. Connect the hand pump to the top waste gate chamber port and

suck it down to about 15-20in vacuum.

The waste gate upper chamber should hold vacuum. If it is holding vacuum,

you can quickly remove the hose and you "may" hear the waste

gate valve "CLUNK" back down to verify the waste gate is not

stuck.

The waste gate valve normally moves about 15mm when it is fully open.

Go to the Waste Gate Spring

Installation page for details on inspecting the WG diaphragm if

you suspect you have a leak.

In some cases if a stiffer waste gate spring has been installed incorrectly

with no upper perch support, the waste gate valve shaft will operate

with too much force to the side and can wear out the wastegate valve

guide. This worn out guide can allow boost leaks through the waste gate.

Engine Control Unit (ECU)

Vacuum/Boost line

In order for the ECU to work correctly, it must receive an accurate

pressure signal (vacuum or boost) from the intake manifold. There is

a plastic line with rubber hoses on each end connected from the ECU

to the intake manifold.

The vacuum/boost line (Green plastic line and rubber hose) from the

intake manifold to the ECU should be checked for leaks if you are getting

too much boost or a fault code 2221, 2222 or 2224. You can connect a

hand vacuum pump to the line after removing it from the back of the

intake manifold and see if it holds vacuum. If you have access to compressed

air and have an accurate pressure regulator, you can apply 10-15psi

to the vacuum/boost line and listen for any leaks.

If you turn on the ignition, (Don't start the engine) you can read the

boost pressure off the digital instrument panel boost pressure display,

and see if it corresponds to the actual pressure applied to the ECU

line from the air pressure regulator. Be careful when applying pressure

to this line, and avoid exceeding 20 psi or you could damage the internal

ECU pressure sensor.

The 1991 200TQ 20V Motronic ECU has the moisture trap located next to

the ECU underneath the kick panel cover that can leak. The S4/S6 has

the moisture trap located underneath the plastic cover on the firewall

at the back of the engine compartment.

It is very common for the hose to get blown off the moisture trap on

the S4/S6 vehicles and cause the vehicle to have low boost and run poorly

in the "Limp Home" mode. The S6 may have the moisture trap near the

ECU. I recommend replacing the crimped on clamps with conventional screw

type hose clamps at this moisture trap location.

Turbo Bypass Valve and Intercooler

leaks

This valve should be removed and checked as this can cause a loss in

boost pressure if the internal diaphragm is leaking. Use a handheld

vacuum pump connected to the small hose fitting to check this valve

operation. It should hold vacuum and open and close freely.

This bypass valve relies on boost pressure acting on this internal diaphragm

to hold the valve closed when the engine is making positive manifold

pressure (above 1.0 bar absolute boost pressure) so you should check

the small hose connected to this valve.

The 1991 Audi 200TQ 20V often had problems with the vacuum/boost supply

hose for this bypass valve getting burned/toasted as the hose was run

along side the exhaust manifold area. Remove the heat shield and inspect/replace

the hose as needed.

Rerouting this hose away from the exhaust area is a good idea. This

bypass valve opens during manifold vacuum conditions (below 1.0 bar

manifold pressure) to allow intake air to circulate around the turbo

cold side impeller.

This bypass valve helps to reduce turbo lag and keep the turbo spinning

during transmission shifting when the engine is producing boost. It

also helps to prevent boost pressure spikes from causing leaks or damage

to the intercooler or connecting hoses.

Audi Bypass Valve Info:

The 1991 200TQ 20V with 3B engine originally used a bypass valve with

the Audi part number 034 145 710 which had the metal reinforcement plate

on the diaphragm, this bypass valve may have had the Bosch 0 280 142

106 part number on it.

An Audi Service bulletin: Group 21 Number 00-01 Dec. 8, 2000 was issued

that described a problem with the Audi TT's that were equipped with

the ATC, AMU and AWP code 1.8T engines. A groaning, howling or rattling

type noise may be heard to come from the bypass valve.

A new Bosch bypass valve was introduced (Audi # 06A 145 710N) to address

these complaints. There is a Bosch equivalent part number for this new

valve, and it is reported to be a good replacement valve for other Audi

turbocharged engines utilizing a bypass valve.

Note: The normal failure with these plastic Bosch bypass valves, is

the rubber diaphragm develops a tear, either near the outside edge of

the diaphragm, or at the sealing surface.

A few aftermarket performance companies have a new all metal, version

of the bypass valves, one is called the "Bailey" valve, and

one I believe is called the Forge valve. I have not tested these valves,

so I can't comment on their effectiveness. The intercooler end cap seals

can leak under high boost and you should install some large straps or

one or two large hose clamps around the intercooler to hold it together

under high boost.

Many hydraulic supply houses carry the screw type hose clamps that are

4 ft long which fit around the intercooler nicely. Because there normally

is an oil mist flowing through the intercooler, any leaks around the

intercooler seals will show up as oil seepage out of the intercooler

end caps.

In some cases you can carefully re-crimp the aluminum tabs that hold

the plastic end tanks on to tighten up the end cap seal. The internal

intercooler rubber seal on the inlet side that seals the internal upper

and lower sections of the intercooler should be checked when you remove

the hoses from the intercooler.

Here is a picture of the larger single pass intercooler from the 1991

200TQ 20V.

There is an O-Ring on the inside of the intercooler inlet on these intercoolers

that seals this pipe to the intercooler. This O-ring should be checked

for leakage and replaced if necessary.

The Audi Part number is N 904 324 01, designated as a round seal 70X4N

Boost Hose Leaks, Wastegate

valve boost leaks, Turbo intake hose

Often times on high mileage (100k>) cars, the turbo hoses begin to

leak boost pressure from loose hose clamps and in other cases when running

higher boost above the stock 12psi (1.8 bar absolute) levels, the original

boost hoses can tear and split open.

You can make a pressure test cap to pressurize the intake/boost hose

system to 15-20psi and look for any leaks from the turbo intake hose,

to the turbo exit hose, from the intercooler to intake ribbed hose,

into the throttle valve and finally to the intake manifold. You should

remove the oil cap and pinch off the breather hose at the intake manifold

connection to avoid pressurizing the crankcase.

This test cap can be made using a 3 inch black plastic sewer pipe cap,

and a bolt in tire valve stem. You insert this test plug into the turbo

intake hose after removing the hose from the MAF sensor. You may need

to use a pressure regulator with your air compressor to limit the pressure

of the system to 15-20psi.

Common boost leaks: 1991 200TQ: The accordion-style hose that connects

the intercooler exit to the intake manifold normally rots (from oil)

over time and can split at the bottom between the ribs while under high

boost. On the later 1992-95 S4, the ribbed hose from the boost pipe

into the intercooler underneath the engine will often split in the ribbed

area for the same reason.

Remove and check them. If your car has over 100,000 miles on it and

this hose has never been replaced, save yourself some grief and buy

a new hose. Samco has some heavy duty silicone replacement boost hoses

for the Audi 20V's.

The turbo exit hose can also split on the 1991 200TQ 20V and on the

S4's where the bypass valve hose is melded into this turbo exit hose.

Many folks are running over 20psi with the stock K24 Turbo, and if you

get a severe boost hose leak, you can over-spin the K24 into destruction.

In some rare cases the Wastegate valve guide will be worn excessively

and will leak boost into the exhaust system. This can be caused

by using stiff wastegate springs with a loose or poorly mounted upper

spring perch in the wastegate cap.

Turbo Intake Hoses:

The large turbo intake hose with connections to the bypass valve, breather

pipe and Mass Air Flow sensor should be removed and checked for any

cracks as this will allow un-metered air inside the engine.

While you have the intake hose off the turbo, you may also want to check

the cold side turbo shaft for excessive play. The K24 turbo Audis spec

the max end play to be 0.00354 inches, and the cold side compressor

side play to be no more than 0.0259 inches. Normally you need a dial

indicator to accurately measure this.

You should also look for any metal shrapnel caused by worn turbo bearings

which may have allowed the turbo compressor blade to rub against the

turbo housing. The turbo exit hose (turbo pressure) going to the intercooler

should be removed and checked as well. The 1991 200TQ 20V has a metal

boost pipe that is inserted into the intercooler inlet uses an O-Ring

for sealing this connection, see section below for details if you see

evidence of a leak at this point.

Vacuum Leaks-Breather Hoses!

You need to make sure your engine’s various breather/vacuum hoses and

turbo intake and pressure hoses are in good shape. Leaks anywhere in these

hoses can cause lean or rich running and poor starting. Vacuum leaks would

typically cause lean running, pressure leaks after the turbo could cause

slightly rich running. In some cases it is not sufficient to just visually

look at these hoses without first removing them!

On the 1991 200TQ 20V with the 3B designated engine, the large breather

hose coming from the side of the engine that is routed around the back

of the engine typically gets rotten and mushy on the inside part of the

hose facing the engine block.

Often times the hose can collapse on itself or will split open on the

back side. This hose does not have hard vacuum applied inside like the

10V Audi Turbo MC engine but leaks could allow un-metered air into the

engine.

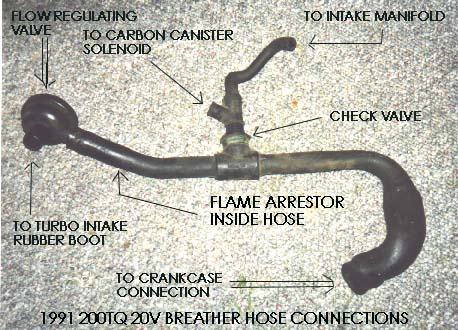

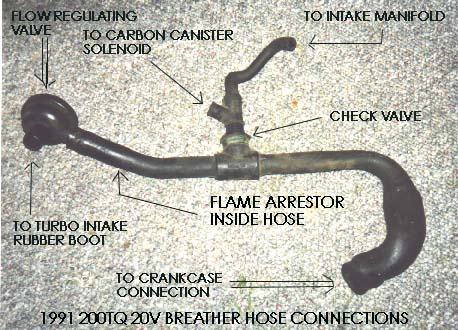

Here is a photo of the 1991 200TQ 20V breather hose, Audi part # 034 103

221AF, Pressure or flow regulating valve (034 129101A), check valve or

what Audi calls the bleeder valve (035 103 245A) , and the small special

molded hose (034 133 367C) , that connects to the intake manifold and

the carbon canister solenoid valve.

The spiral wire brush flame deflector inside the hose has Audi part number

035-103-477A Always check with your Audi dealer parts person to verify

these numbers.

This 1991 200TQ 20V breather hose is routed around the back of the engine

and one end connects to the round black crankcase pressure regulator valve

near the back of the valve cover.

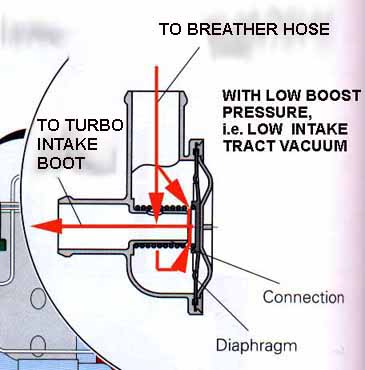

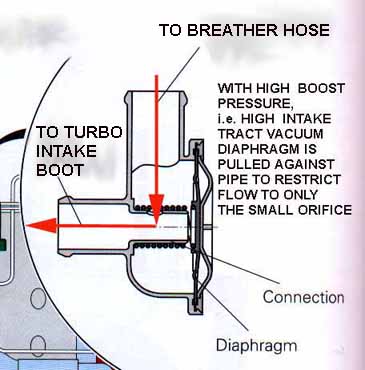

This black regulator valve, controls the flow of crankcase fumes to the

turbo intake boot [1]. The valve has two ports inside, one is approximately

0.400 diameter and a smaller one that is approximately 0.180 inches. The

larger port and the smaller port are open during low boost operation but

when the turbo makes enough boost and flows enough air to produce a vacuum

on the suction side of the turbo, the regulator valve diaphragm sucks

closed and blocks off the larger port.

This leaves only the smaller port open to flow crankcase breather fumes.

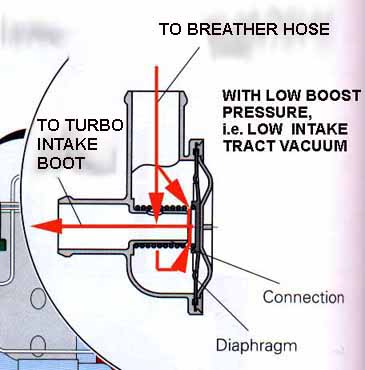

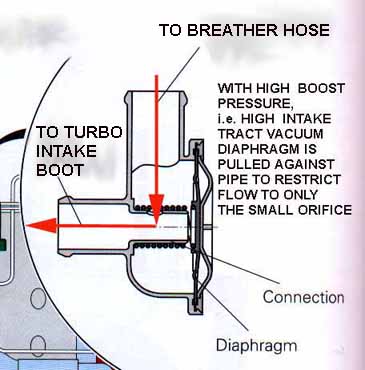

Here are two diagrams showing the valve in operation under low boost and

low intact tract flow with both the 0.180 and the 0.400 ports open, the

second diagram shows the operation under high boost, high intact tract

flow, high intact tract vacuum conditions when the internal diaphragm

is pulled against the 0.400 opening to close it off, leaving only the

smaller 0.180 port open for reduced flow.

Diagrams courtesy of Audi of America

NOTE: On the 1991 200TQ 20V there is also a flame arrestor (spiral wire

brush) inside this breather hose on the end near the black flow regulating

valve, so be sure to remove this flame arrestor and install it in the

replacement hose. This flame arrestor prevents a back fire in the intake

boot from traveling into the engine crankcase. I have not verified if

the S4 uses this same flame arrestor.

This 1991 200TQ 20V breather hose also has a Tee in the center of the

hose, which connects to the intake manifold via a flow regulating one

way check valve and a molded rubber hose. The check valve will close under

positive manifold "boost" pressure.

On the 1991 200TQ 20V the carbon canister solenoid valve also connects

at this tee location. The carbon canister solenoid allows gasoline fumes

from the fuel tank that are stored in the carbon canister, to flow into

the intake manifold when the engine is running.

The carbon canister solenoid valve is closed when the engine is off to

prevent fuel tank fumes from entering the engine and causing a rich mixture

when starting. If the carbon canister solenoid or electrical connection

should fail, this valve also has an internal diaphragm which will open

under engine vacuum to allow fuel tank fumes to flow into the engine.

It is very difficult to see this connection to the intake manifold hose,

as there is very little room behind the engine.

NOTE: On the 1991 200TQ 20V if you are working around the back of the

engine and replacing this breather hose, make sure you mark and identify

any hoses or electrical connectors before removing them. In one instance,

I ran across a car that had the electrical connectors from the heater

valve temp sensor, the carbon canister valve, and the engine coolant temp

sensor mixed up and connected to the wrong item.

The color coding on the connector, may not match up with the item it plugs

into. The Bentley manual shows that the Engine Coolant temp sensor connector

should have two wires, one Gray with brown stripe, one Green with black

stripe. The Carbon Canister solenoid connector has two wires, a Red colored

wire and a White with red stripe wire.

The heater valve coolant temp sensor electrical connector should have

two wires, a Yellow and red stripe wire and a Brown with black stripe

wire. The two small idle stabilizer hoses should be removed and checked

also as they can get blown off from the pressure. Any of the smaller hoses

connected from the intake manifold to the heater/AC system should be checked

for cracks or leaks.

Are you using the correct Spark

Plugs?

The 20V Turbo engines as found in the 1991 200TQ and in the later 1992-95

S4/S6 should have installed the Original Equipment F5DPOR BOSCH PLATIN

Electrode Spark Plugs.

Be aware, that they are more expensive than normal spark plugs. These

F5DPOR plugs have a single thick platinum electrode.

These thick electrode Bosch PLATIN plugs should not be confused with

the cheaper Bosch platinum spark plugs that have a thin center electrode.

There are Bosch 3 electrode copper core plugs (FR5 DTC) that cross reference

to the F5DPOR, but I don't recommend using these 3 electrode copper

core plugs, use the correct single thick electrode platinum F5DPOR plugs.

It is also a good idea to check the torque of the spark plugs,

every 5k miles if you are running high boost levels, as many have found

the plugs to come loose on the 20V Turbo engines.

New Bosch F5DPOR plugs are spec'd to be tightened to 22 lb-ft, used

plugs will normally require slightly more torque when re-installing

them.

It is also a good idea to replace the valve cover gasket on the 20V

Turbo engines, if you have higher mileage on your engine, and still

have the original gasket.

The center valve cover gaskets around the spark plug holes can leak

and mess up the plug area and the spark plug wire ends.

Ignition Wires causing misfire?

Distributor Cap shorting out to black shield cover?

For the 3B engine, the Audi OE ignition wires have a stranded copper

wire and use resistive spark plug connectors that each have ~5k ohms.

The other end of the ignition wire that plugs into the distributor cap

has a resistive connector end with approximately 1k ohms.

In many cases the spark plug ends can have too much resistance and will

cause a misfire under load, in some cases the resistance measurement

will test OK, but you will still get a misfire due to the ignition wires

or connectors.

On high mileage engines with the original ignition wire set, the spark

plug wires and connectors can arc to the valve cover under high load/high

boost.

I have also found in rare cases that the distributor cap can arc internally

to the inside of the outer black plastic shield which can cause strange

running conditions and misfires that are very difficult to locate.

The distributor cap below was arcing from the coil wire center post

to the black cap shield.

It came from a 1991 200TQ 20V that exhibited hard starting intermittently,

would stall at idle at random times, and would cutout under full throttle

conditions that felt like the fuel pump quit. The ECU would store false

fault codes for the RPM and Reference Sensors, as well as a false fault

code for the Hall Effect Sensor in the distributor. The arcing area

was on the back side of the cap and was not visible with it installed

on the distributor.

1992-97 Audi S4/S6 Five Cylinder 20V turbo engine:

The coil leads that connect from the coil to the spark plug

also have internal resistance (~5k ohms) which can fail and cause a

misfire under heavy load even if the resistance measures OK. Additional

information below covering other ignition problems.

Ignition misfire on S4/S6 with coil

over direct ignition system

Are you using the correct Distributor

Rotor for the 3B 20V Turbo Engine in the 1991 200TQ ?

The 3B designated 20V Turbo engine in the 1991 200TQ used a unique Distributor

Rotor with a narrow tip that can be difficult to find in the US. This

narrow tip rotor is required to provide the precise ignition timing

at the higher RPM's and to prevent any ignition cross firing inside

the distributor cap. Some people have reported engine damage (bent rod)

that may have been caused when the incorrect cylinder was fired under

very high boost.

The Bosch parts catalog shows the INCORRECT distributor rotor

(Bosch 04170 or the 1 234 332 350 R1) for this 20V Turbo application.

This Bosch 04170 (1 234 332 350 R1) rotor has a wider electrode tip

measuring 0.710 inches (~17-18mm).

The Audi part number shown for this INCORRECT rotor is 052 905 225C

The correct Bosch Distributor Rotor with the narrow tip for the 3B engine,

has the last 3 digits as -414.

The correct narrow electrode tip rotor measures only 0.432 inches, (~11.0mm).

The Bosch part number may also have the designation "R1" at

the end, which indicates the rotor has a 1k ohm resistive element from

the center to the tip.

The original 3B distributor rotor with narrow tip. The other important

thing to note about this rotor, is that it is glued onto the distributor

shaft, and it needs to be broken or crushed when removing it from the

shaft using a pair of channel lock pliers. You can also use a dremel

cutting wheel to cut off the old rotor.

Be careful not to damage the shaft when crushing this rotor and removing

the left over pieces. You need to thoroughly clean the distributor shaft

with some sand paper and some non residue cleaning solvent, (loctite

primer solution is also recommended) and then use Loctite 640 (or equivalent)

to secure the new rotor in place.

The Loctite needs at least 4 hours to dry before you can start the engine.

This operation is not easy given the restricted access to the distributor

on the 3B 20V Engine. You can remove the intake manifold to allow easier

access to the distributor.

NOTE: Even though it is possible to pry off the anti-tamper plate from

over the distributor hold down nut with the intake manifold installed,

I recommend taking the extra time and remove the intake manifold to

allow easy access to the ignition distributor.

With the intake manifold removed, you may want to replace the coolant

pipe O-Rings, seal and Turbo coolant hose while you have the intake

manifold removed. See section below for details. When you unbolt the

intake manifold, you can leave the fuel lines attached to the intake

fuel rail, and just use some heavy wire to tie up the intake manifold

out of the way as shown in the Bentley repair manual.

A long (over 8 inch) 6mm allen wrench tool is usually required to remove

the intake manifold bolts. (VAG1669 or equivalent). You can also use

a long 1/4 inch drive extension, with a 6mm socket and a 6mm allen wrench

socket shaft in combination to access these intake manifold bolts but

this is a little tricky.

The intake manifold gasket should be replaced and the bolts should be

torqued to 16 ft-lbs upon reassembly, start in the middle and work your

way outward when torquing them down. Once you have the intake manifold

tied up out of the way, you can cut off the anti tamper cover (a Dremel

cutting wheel works here as well).

Before you loosen the distributor hold down nut, you should first set

the engine to be at TDC with the flywheel O mark lined up, and the distributor

rotor pointed at the line mark on the rim of the distributor. Once you

get the engine rotated to the correct position, you can remove the hold

down clamp and pull out the distributor. Removing the distributor gives

you better access to the distributor so you can either crush the old

rotor with some pliers, or cut the old rotor off "carefully" using a

dremel cutting wheel.

As mentioned, you should remove all traces of the old rotor with some

200-300 grit sandpaper, and use some non-residue solvent (loctite primer

solution is also recommended) to clean the distributor shaft before

you apply some Loctite 640 to the inside area on the new distributor

rotor. Insert the rotor over the distributor shaft with the key way

lined up. Allow to dry for at least 4 hours before starting the engine.

The Bentley Repair manual also indicates that you should use the special

tool #3233 to accurately line up the distributor rotor tip when setting

the basic distributor position in relation to the flywheel O TDC mark,

and the cam gear dot mark.

The Bentley also states that you should turn the distributor body counter-clockwise

when you line up the rotor with the 3233 tool and then hold the distributor

body with your hand while you tighten down the hold down nut. NOTE:

The R1 in the distributor rotor part number refers to the fact that

this rotor has a 1K ohm resistor between the center electrode and the

outer tip electrode.

This rotor resistor can sometimes burn up after many years and cause

a no start, and prevent the engine from running. You may also want to

replace the valve cover gasket, the main breather hose, any vacuum hoses

and other hard to reach coolant hoses and coolant temperature sensors

while the intake manifold is moved out of the way.

See section below for replacing the Coolant Pipe O-Rings, seal and turbo

coolant hose while you have the intake manifold off.

Coolant Pipe O-Rings, Seal and Turbo

coolant hose replacement

Knock Sensor Intermittent? Hesitation?

Low Power? Check Engine light On?

If your 1991 200TQ 20V is running poorly or the "Check Engine" light

has come on, it is possible that the ECU is detecting a fault in the knock

sensor system caused by a loose, defective or intermittent knock sensor.

There may also be a problem with the knock sensor wiring or connectors.

Go to

20V Engine Knock Sensors section for

details on the 20V Turbo Engine knock sensors.

The newer style "replacement" knock sensors have gold plated terminals

and the wiring harness connector terminal pins should be replaced with

these gold plated versions as well.

Some of the 1991 200T/Q's have the "Check Engine" light bulb removed from

the dash, so if the car is having a problem with one or both of the knock

sensors, you may not know it.

The "Check Engine" light should come on with the ignition key turned on

to the first position.

Air Temp Sensor

The air temp sensor that the ECU monitors to regulate boost and ignition

timing can have poor external connections or can have intermittent connections

on the small thermistor at the tip of the sensor. This sensor is located

in the intake manifold near the throttle valve.

The wire terminals are normally soldered or spot welded to the air temp

sensor. Factory replacement air temp sensors use a separate connector

with gold plated terminals instead of the soldered/welded terminals on

the original sensor.

Go to the

20V Air Temperature sensor page for

details on checking the operation of this air temp sensor.

O2 Sensor Replacement

The O2 sensor should be replaced if it has over 60k miles on it, or

if you have a hesitation, lean surging during light throttle conditions,

poor cold running problems during the first 30-60 seconds of engine

warm up, poor gas mileage or emissions related failures.

Older O2 sensors can get contaminated and will respond too slowly to

correctly adjust the mixture and can cause poor running when transitioning

from light throttle to full throttle conditions.

See these sections for details on testing and /replacing the O2 sensor.

Oxygen (O2) Sensor, Open and Closed Loop

Operation

Oxygen (O2) Sensor, Testing

Bosch Replacement 3 Wire Oxygen Sensor

Fuel Filter clogged

or restricted?

Fuel contamination?

A clogged or restricted fuel filter can cause cutting out under high

load and high boost in 3rd/4th/5th gear that often may feel like an

ignition misfire.

It is a good idea to change out the filter every 30k miles or every

2 years.

The filters are normally designed to absorb any moisture in the fuel

which can cause the filter media to swell and restrict fuel flow.

The ethanol based fuel can make this issue worse. After removing the

filter, if you can't easily blow through the filter, it needs replacement.

If I suspect fuel contamination with excessive water or dirt etc, I

like to remove the filter and "carefully" blow the remaining

fuel out of the filter into a clear glass bottle to check for any crud/water.

Fuel Pressure

Regulator Diaphragm Leaking, Running rich?

Regulator Vacuum/Boost hose leaking or disconnected,

Poor running, cutout under full load?

In some cases the fuel pressure regulator diaphragm is ruptured and

will leak fuel into the vacuum/boost port and get sucked into the engine

at the other end of the hose where it attaches to the intake manifold.

Check the vacuum port for any fuel after removing the vacuum/boost rubber

hose line.

Also verify the vacuum/boost hose from the intake manifold to the fuel

pressure regulator vacuum/boost port is not leaking.

If the fuel pressure regulator does not get good engine vacuum at idle,

this will cause the fuel pressure to be increased and this would cause

rich running at idle.

The regulator also requires boost pressure acting on the diaphragm to

ensure the fuel pressure is increased above manifold boost pressure

to maintain the fuel pressure drop across the injector.

Insufficient fuel pressure under high load, high boost can cause cutting

out in 3rd/4th/5th gear.

The S4/S6 incorporates a screen inside this pressure regulator which

could get clogged with extremely contaminated fuel.

Multi-Function Temp. Sensor-Defective?

One additional sensor to check when having low boost problems (1991

200Tq 20V Only) , is the Multi-function Temperature sensor.

This sensor is mounted underneath the intake manifold, on the coolant

pipe on the 20V Turbo Engine.

This Multi-function temp sensor uses a 4 terminal connector which is

normally is covered with a protective rubber boot. The newer style replacement

Sensors will have only 3 terminals as they simplified the internal design

of this sensor and eliminated the +12V supply to this sensor.

Go to 20V Engine Multifunction Sensor section

for more details on this sensor.

Audi Parts

Coolant Temperature Sensor:

The Engine Control Unit uses a coolant temp sensor that should be tested

if cold or hot start problems or problems during engine warmup are occurring.

Go to 20V Engine Coolant Temperature Sensor

section for details on checking this sensor.

The engine must warm up quickly and run hot enough for correct boost

control and timing control and best performance. To ensure correct operation

and for the highest fuel mileage, only use the 87 Celsius Thermostat

See cooling system section below.

Check ECU Connector Terminals

for Corrosion

If you are having some running or boost problems, you may want to inspect

the ECU Connector terminals for any subtle corrosion on the tin plated

terminals and use some electronic contact/terminal cleaner on them,

along with some contact enhancer.

The plastic bag cover over the connector should be installed correctly

to avoid any water or moisture from dripping down onto the connector

and wiring. Sometimes just removing the large ECU Connector will cure

some problems as the action of removing and installing the large connector

wipes clean the connector terminals.

Check Engine Ground Cable and Intake

Manifold Ground wires

Throttle Cable Adjustment

It is a good idea to check the throttle cable adjustment to ensure

the throttle is being opened all the way when the gas pedal is pushed

all the way down to the floor. With the engine off, have a friend push

down on the gas pedal inside the car, while you check the throttle lever

under the hood. The throttle lever should be pulled all the way open

with the gas pedal pushed down all the way to the floor

Idle Switch or Throttle

Potentiometer Defective?

The Throttle switch/Potentiometer has 2 functions, (1) the idle switch

tells the ECU that the throttle has closed so it can perform deceleration

fuel cutoff and correct idle speed regulation.

(2) The Potentiometer (variable resistance) tells the ECU both the throttle

position and the rate the throttle is opened and closed.

This resistance measurement is used with the ECU voltage supply to provide

a varying output voltage the ECU reads to set the correct amount of

boost produced.

A defective Throttle Potentiometer may prevent the correct operation

of the Waste Gate (WG) solenoid system that the ECU uses to adjust the

turbo boost.

Go to 20V Throttle Switch/Potentiometer

page for details on checking the Throttle Potentiometer.

Note: Using a stiffer Waste Gate spring is a great idea on the MC engines

and possibly on some 20V engines with non-stock Turbos as it will improve

the rate at which boost is produced, but...... it can mask problems

with the ECU system components (Throttle switch/throttle potentiometer

etc.) as the boost will be mostly controlled by the stiffer Waste Gate

Spring.

Check basic engine timing, flywheel,

camshaft and distributor rotor position

You should check the basic engine timing, the flywheel should be placed

at TDC with the O mark lined up in the transmission window, the camshaft

gear line should be set at the top mark on the valve cover, and the distributor

rotor should be set to the #1 cylinder line on the rim of the distributor.

I have run into a few 20V engines that had loose front crank damper pulley

bolts, which allowed the crank timing gear to move side to side and shear

off the keyway which altered the crank/cam timing. It is likely that the

previous timing belt repair work was done incorrectly, and the mechanic

did not torque the crank pulley bolt enough.

The line on the dual mass flywheel in the AAN S4/S6 20V turbo engines

can be tough to see through the hole in the transmission housing when

setting the engine to TDC, it helps to put a white paint mark on this

line. In some cases on the 3B 20V Turbo engines, the timing belt will

stretch over time, and will change the cam/distributor timing enough to

cause problems for the ECU when it processes the distributor hall effect

signal to set timing and boost.

The Bentley manual has the details on setting these 3B distributors correctly,

normally this is done when the timing belt, or distributor is replaced

or if the camshaft is removed. A special tool #3233 is normally used to

line up the distributor rotor with the line on the distributor body, which

can help as it is difficult to see the distributor behind the intake manifold.

See photo below

If you don't have the 3233 tool, a small mirror can also be used to correctly

line up the distributor rotor and the line the rim of the distributor.

See section below on using the correct distributor rotor for these 20V

"3B" designated engines.

Altitude Sensor ok?

Idle Stabilizer Valve (ISV)

The idle stabilizer valve (ISV) can also stick from oil/crude built

up inside and this can cause strange high idle conditions.

Cleaning the ISV with carb cleaner may help.

With the ISV removed from the engine, but with the electrical connector

on, I like to run the ECU Output Tests which cycle

this ISV open and closed while you spray the cleaner inside.

The hoses on the ISV valve to the intake manifold can blow off under

boost, or can be cracked and cause a loss in boost pressure. This engine

uses the ECU to control the idle stabilizer valve, which is a rotary

type valve.

Go to 20V Idle Stabilizer System

section for details on checking the operation of this rotary valve

Idle Speed/Mixture Adjustment/Check:

NOTE: The Idle speed and Idle mixture on the 20V engine are not adjustable.

The 20V Motronic Engine Management system has the capability to adjust

the fuel mixture over time (adaptive system) so periodic adjustments have

been eliminated [1].

Fuel Injectors

Leaky injectors can increase the hot/cold starting times but the

20V engines are not as susceptible to this leaky injector problem as the

previous 10V Engines. Some high mileage vehicles or vehicles that are

driven over repeated short distances without proper warm up may exhibit

fuel spray problems. Dirty/clogged injectors with poor spray patterns

can cause poor low end performance and uneven performance when cold. There

are several companies that offer fuel injector cleaning and balancing

etc.

Excessive Intake valve carbon deposits can also cause cold running problems

as the carbon acts like a sponge, soaking up the fuel at first. With severe

carbon buildup some repair shops can use a walnut shell blasting device

to clean off the carbon buildup. Lighter buildup can be removed with the

use of a fuel additive or a fuel with Techron.

Coolant Pipe O-Rings, Seal and Turbo

coolant hose replacement

Cooling System checks

The engines cooling system needs to be working correctly before you

decide to up the boost on your car.

All the coolant hoses should be checked/replaced and the cooling system

should be flushed out and refilled with the correct mix of coolant.

When you have the upper radiator hose removed, check the condition of

the plastic upper radiator hose fitting, as these plastic fittings can

crystallize and break off while driving.

On the 5000TQ and the 200TQ, the plastic heater valve located at the

back of the engine near the exhaust waste gate should be replaced if

it has high mileage, they have a bad habit of getting brittle and breaking,

causing a loss of coolant and some rapid overheating.

The S4/S6 have this heater valve located away from the heat of the engine

underneath the plastic cowling near the windshield, so they may not

need to be replaced as often.

The S4/S6 do have a plastic Tee fitting that has the Climate Control

temperature sensor, which can get brittle over time and break that will

cause you to lose most of your coolant while driving.

This Tee fitting should be replaced on high mileage cars to avoid a

sudden loss of coolant. We keep these in stock , if you need one.

The Heater hose fitting at the back of the engine block is also plastic

and can crack internally which will cause a coolant leak, best bet is

to replace both of these plastic fittings.

The thermostat should be replaced with the factory specified 87 degree

Celsius version if you still have the original one installed, or if

it is several years old. Often times a malfunctioning thermostat will

cause engine running problems, and poor gas mileage if the engine is

running too cool.

You may also want to replace the short piece of coolant hose located

underneath the intake manifold, as this hose can blow and make your

life miserable if you have to change it when the engine is hot.

Audi sells the hose in bulk lengths, or you can look for similar sized

coolant hose from an aftermarket parts supplier, Gates etc. I don't

recommend using fuel line or other hose not designed for high temperatures.

The after run cooling fan and turbo pump should be checked for correct

operation.

Go to the Cooling system page in the Troubleshooting

section for additional details.

Exhaust System Issues

You should have the exhaust back pressure checked by a muffler shop if

you have low boost conditions and suspect a plugged catalytic converter

or muffler/exhaust system. They can use the pre-catalytic converter sniffer

pipe bolted to the intake manifold to do this, or they can drill a small

hole in the exhaust pipe to insert the pressure gauge pipe.

A low pressure (0-10 psi) fuel pump pressure gauge can be used for this.

Typically with the car idling in neutral, as you slowly rev the engine

to 4000 RPM and hold it at 4000 RPM, the exhaust back pressure should

not increase above 1-2 psi. If you run a long hose from the sniffer pipe

to a gauge inside the car, an assistant can check the exhaust back pressure

while you drive the car.

Test Example: When the car is driven and under load in 3rd gear at WOT

and near redline, it is not unusual to see over 4-7psi of back pressure

when running 1.8 bar of boost pressure. The older catalytic converters

can create some of this back pressure and may need to be replaced as the

car gets over 75K miles.

The RS2 type exhaust manifold is recommended for improving the exhaust

flow out of the head and rumor has it, to prevent burned exhaust valves

when more extensive ECU and Turbocharger mods are performed. As mentioned,

the catalytic converter and muffler system can get plugged or restricted

over the life of a car which may cause poor running with low power.

Catalytic Converter meltdown can occur if extremely rich mixture levels

occur in the combustion chamber which are not thoroughly burned which

allows high levels of raw gasoline (Hydrocarbons) to pass into the catalytic

converter. If this occurs under engine load conditions and is followed

by normal lean running or idling the catalytic converter will get very

hot and damage may occur. Ignition misfires can also dump raw fuel or

hydrocarbons (HC) into the catalytic converter and this will also cause

meltdown of the ceramic honeycomb material if the engine is driven under

load.

If you ever need a reminder to let your engine run after a high boost

run, just open up your hood at night and see the red hot exhaust manifold

and turbo! Even with the water cooled turbo you should let the car idle

for several minutes.

It may take 10-15 minutes of normal low boost driving before the exhaust

manifold/turbo cool down. It is a good idea to avoid high boost initially

after starting a cold engine until the oil temp gets up to 60C (this is

recommended in the factory operators manual).

Drive Train Issues

Driving with more boost/horsepower places more stress on the transmission,

clutch, suspension system and tires. The Audi I5 turbo engines are very

robust motors but running Higher Boost levels obviously places some additional

stress on the internal engine components.

The two hydraulic engine mounts and the rear transmission mounts should

be checked, the exhaust side (passenger side) engine mount is subjected

to a lot of heat. A defective hydraulic engine mount on this side tends

to place more stress on the exhaust manifold/system.

Of course the tires, CV joints, wheel bearings, shocks, sub frame bushings

and other suspension bushings/parts subject to wear and tear should be

replaced where necessary. Having more power will make the car a handful

to drive if you have a worn out suspension as you will discover in short

order.

Better to fix it now than to crash and burn it later.

References: [1] Audi of America, Technical service training publication:

"The New 20V Turbo Engine for the Audi 200 Quattro-publication

All rights reserved.

Copyright © SJM Autotechnik™ , all rights reserved

Return to

Troubleshooting Tips page.

Return to

SJM Autotechnik™ main page.