1982-85 ur-Quattro Coupe, 1985-1990 5000/200, Turbo and Quattro,

Waste Gate Spring Details:

A stiffer Waste Gate spring prevents the waste gate valve from opening

too quickly before the turbo can produce boost. This delayed Waste

Gate "cracking" improves transient throttle response and allows the

boost to increase at a quicker rate.

1.8 Bar Springs are available for the 1986-88 5000T/Q and for the

1989-90 200TQ when using a modified ECU to allow 1.8 bar boost.

It is very important that you ensure the ECU Waste Gate Solenoid boost

control system, the Wide Open Throttle (WOT) switch, air temperature

sensor and knock sensing system are working correctly, BEFORE you install

a stiffer 1.8 bar Waste Gate Spring after you have installed the 1.8

bar modified ECU.

The stiffer 1.8 bar Waste Gate spring will make the turbo produce

higher boost even if the ECU Waste Gate Solenoid boost control system,

the WOT fuel enrichment system or the knock sensor system are not

working correctly.

Go to the "ABC's

of Running High Boost" page for details on checking the ECU systems

mentioned above.

NOTE: Running the engine with higher boost without the correct fuel

enrichment, without a working air temperature sensor or without the

knock sensing system can damage the engine from detonation (pinging).

In most cases "light" engine pinging will NOT be heard by the driver.

Sustained pinging can eventually lead to head gasket failure or

piston ring land damage.

If you running my modified ECU and 1.8 bar WG spring, you may occasionally

experience the ECU safety feature which shuts off the fuel pump relay

at ~1.95 bar. This can occur with certain air temperatures or if you

have modified your exhaust system for better flow. You will need to

reduce the WG spring tension slightly, by modifying the upper WG cap

to shorten the upper perch length. The earlier 84-85 5000T automatic

vehicles often had an adjustable upper WG cap, which can be used on

the later 1986-90 5000/200T/Q's.

Testing the Waste Gate Diaphragm

Before you remove the Upper Waste Gate Diaphragm cap to install

the waste gate spring, it is a good idea to test the waste gate diaphragm

for any possible leaks. Use a hand vacuum pump (Might Vac or equivalent)

to apply vacuum to the small hose fitting on the top of the waste

gate cap. The upper chamber/cap should be able to hold vacuum, you

can suck it down to about 15-20 in Hg and wait about a minute or so,

to see if the system leaks.

Other Waste Gate system tests can be found at

Waste Gate

and Solenoid Hoses

Waste Gate Spring Installation:

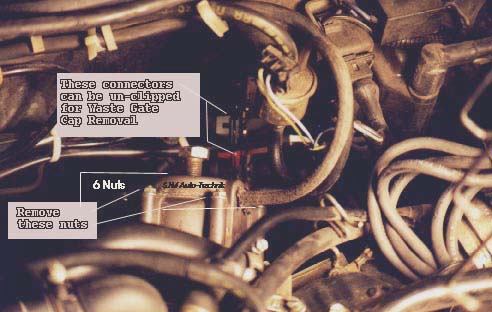

The Waste Gate spring or diaphragm can be removed after removing

the 6 small nuts (8mm, or 5/16) and washers (used on some models)

from the Waste Gate Cap.

On the 1986-88 5000TQ and on the early 1989 200TQ, it may be required

to unclip the 3 connectors mounted on the firewall to allow the Waste

Gate Cap to be removed easily.

You may want to mark the connectors to avoid mixing them up, even

though they tend to go back to their original locations.

Here is a photo of the Waste Gate Cap located at the rear of the

engine compartment.

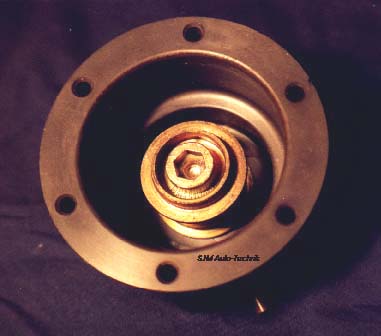

The Waste Gate Diaphragm should be inspected after removing the

Waste Gate Cap. Look for any tears or holes in the Diaphragm. The

picture below shows the Diaphragm after removing the cap and spring.

Install the WG cap over the 1.8 bar spring, while making sure the

spring is centered over the lower spring perch and also that it is

centered against the upper spring perch in the cap. Pushing down the

WG cap over the stiffer 1.8 bar spring requires the use of a large,

(~18 inch) screwdriver or small pry bar. The screwdriver is wedged

against the firewall and used to push down the Waste Gate Cap and

allow you to install two of the small nuts/washers. Be sure to avoid

pinching the wiring harness near the firewall when you slide the screwdriver

between the harness and the firewall as you pry down on the WG cap.

You need to apply even pressure with the long screwdriver to allow

the cap to slide down easily over the studs and compress the stiff

WG spring.

Install the remaining nuts/washers and snug them down using a small

1/4 drive ratchet and 8mm socket. Don't over tighten these small nuts!

Be sure to reconnect the ECU harness connectors at the firewall, or

you will have a car that won't start.....

Waste Gate Diaphragm

Installation:

Five Cylinder 20V Turbo engines: The 20V turbo

engines allow easy removal of the waste gate assembly to allow replacement

of the diaphragm. After removing the wastegate assembly from the engine,

remove the 6 nuts from the upper cap and then remove the cap and waste

gate spring.

Note: Removing the wastegate assembly allows you

to use a allen wrench to hold the valve head and prevent it from spinning

when you remove the upper nut to replace the diaphragm. Additional

details below for the 10V Engines may help as well.

If you are replacing the Waste Gate Diaphragm on 1983-1991

Five cylinder 10V Turbo engines

10V Engine: After removing the WG cap, you need

to pull up the diaphragm slightly from the six studs and then look

underneath for a steel plate underneath the diaphragm rubber lip.

In order to loosen the nut which holds the diaphragm assembly together,

you need to jam a flat bladed screwdriver between the outer Waste

Gate aluminum housing and this round plate that is underneath the

diaphragm. This is not the most elegant way to remove the

diaphragm, but it beats having to remove the entire waste gate assembly.

10V Engine: The nut usually has loctite on the

threads, so it will be pretty tight and tough to loosen. You may need

to use a small propane torch and heat up the nut slightly, to help

break loose the loctite. You need to jam the screwdriver in tight

enough, in such a way as to prevent the Waste Gate lower plate and

valve shaft from spinning. You can try and use a hand operated socket/ratchet

or you can try using an air operated impact wrench to break it loose.

Sometimes the impact wrench ends up just spinning the valve shaft

assembly too fast and prevents the valve shaft from remaining stationary

while turning the nut loose.

Here is a picture showing the wastegate removed from the engine,

and the components after removal of the top nut and the area underneath

the diaphragm.

Installation is the reverse of the procedure, you may want to apply

some high temperature loctite to the valve shaft threads. Torque the

nut to 14 lb-ft, but use caution to avoid tearing the new diaphragm.

It the Waste Gate valve shaft keeps spinning even with the screwdriver

jammed in, you may have to remove the entire Waste gate assembly from

the exhaust system and use a 10mm Hex allen wrench or wide bladed

screwdriver to insert into the bottom of the Waste Gate valve head

to keep it from turning while loosening the upper nut.

Waste Gate Solenoid Boost Control Details

Normally the stock ECU system can control the WG solenoid can add

pressure to increase the boost above the spring pressure by approximately

0.1-0.4 bar. It is limited to how fast it can raise the boost and

normally for best performance, you want to use the stiffest WG spring

possible which is about 0.1-0.2 bar below the boost map values set

in the ECU. People living at high altitudes may want to limit the

boost map values set in the ECU EPROM code to 1.8 bar and use the

stock or 1.8 bar spring to prevent over-spinning the turbo at high

altitudes.

This same WG solenoid setup can subtract about 0.1 bar from the

boost supplied by the WG spring pressure at sea level. You will lose

more boost at higher altitudes if the ECU controlled WG solenoid isnít

working. The WG solenoid does this by connecting the upper WG chamber

to the inlet side of the turbo which is at a slight vacuum under WOT

conditions.

To fine tune the WG spring tension and the over-boost response,

I normally modify the waste gate upper cap to allow the WG spring

tension to be adjustable. On the 5000/200TQ, the spring perch can

be removed from the cap after the allen bolt is removed.

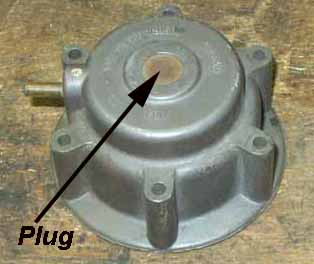

Here is a photo of the Waste Gate cap on the 1986-90 5000/200TQ,

showing the allen bolt

This allen bolt is a pain to get loose as it is loctited in place.

Some times rapping it with a punch can jar loose the threads. Using

an air driven impact gun can also break it loose. Applying some heat

to the cap from a propane torch can also help break loose the loctite.

The ur-Quattro and some of the earlier 1984-85 5000 Turbo vehicles

had a nice WG setup that uses an allen screw and a different spring

perch, making adjustment easier. The ur-Q perch has a wider inner

seat diameter and this is the reason the custom WG springs have a

larger inner diameter.

The exterior plug that covers up the threaded area in the cap can

be removed by drilling a hole in the plug, then screwing in a sheet

metal screw, and finally use some side cutters or pliers on the screw

to pry the plug out.

If you get a 50mm long 12mm X 1.25 thread pitch metric bolt, this

can be screwed into the end of the WG cap to adjust the WG spring

tension. You need to slide the original WG spring perch over the bolt

with one thin nut on each side to hold the perch in place. This will

allow its position to be moved up and down. Some people will also

cut the original perch to shorten it for a greater range of adjustment

using a stiffer spring. Two valve spring shims of the correct diameter

can be placed between the spring and the adjustable perch to allow

the perch to be rotated without twisting the spring and the WG diaphragm.

- Important Safety Information

Copyright © SJM Autotechnik™ , all rights reserved.

Return to SJM Autotechnik™ main

page.